MATERIAL HANDLING

MECHANICAL BIN ACTIVATOR

This equipment is a combination of a mechanical bin activator with a flexible screw conveyor. Whatever the silo capacity the silo discharge unit ZDM guarantees flow control and accurate feeding of your powder product such as quick lime, hydrated lime,

powdered activated carbon, etc.

b. BULK BAG DISCHARGER

Sodimate’s big bag discharger units are designed to store 35ft3 and 70ft

3 capacity big bags, FIBC bags, bulk bags, or super sacs. The big bag can be placed on the frame using standard handling methods, such as a forklift or overhead crane, or the unit can integrate its own

manual or electrical hoist. Common dry chemicals stored in the big bag discharger include powdered activated carbon (PAC), hydrated lime, polymers, soda ash, clay and sand.

c. HOPPER WITH SCREW FEEDER

Our storage hopper is ideal for discharging smaller quantities of product delivered in 50 lb bags, such as lime, soda ash, sand, cement, or powdered activated carbon (PAC). These units feature a ZFP 500 mechanical discharge and feed system.

d. INJECTOR SCREW FEEDER

The injector screw transfers or injects dry chemicals into a sludge mixer, slurry tank or gas stream while isolating moisture, heat and condensation from the dry chemical. Injector screws are used in place of isolation devices such as pinch valves, slide

gates, rotary airlocks, and butterfly valves.

e. SLURRY TANK

Sodimate engineers custom mixing tanks for various slurry solutions ranging from 2% to 30%. Typical slurry solutions include calcium (hydrated lime or quicklime), powdered activated carbon (PAC), sodium bicarbonate (soda ash), potassium permanganate and

clay. Sodimate tanks are made out of black HDPE, and their design and layout is fully customizable. The tanks come fitted with a mixer, valves, detectors, as well as necessary fittings for pumping, draining, over-flow,

and liquid recirculation. Tanks are dust-free and their volumes typically range from 100gal to 1,000gal. Larger tanks up to 700ft3, made of HDPE, epoxy coated steel,

or stainless steel, can also be fabricated.

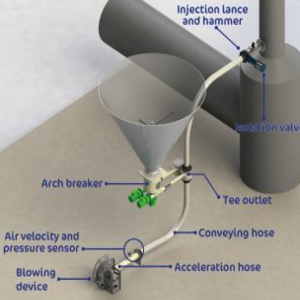

f. PNEUMATIC CONVEYING SYSTEMS

The Sodimate Mechanical Arch Breaker discharges and doses the product stored in the silo or Big Bag emptying stands to a Tee to which the blowing device is connected. Then the compressed air conveys the powder to the injection point through a pipe. The

pneumatic conveying is done in a dilute phase, allowing us to operate with a low pressure and cost-effective blowing device, e.g. a fan or a regenerative blower.

g. LOSS IN WEIGHT FEEDER

For installations that require high powder metering accuracy, instantaneous flow rate image, or consumption totalization, Sodimate can provide a turnkey Loss in Weight system.

The operation is simple, reliable,

with a very high accuracy for industrial applications. This installation allows weight dosing from a buffer hopper placed under or near the silo to the injection point. This mechanism can also be applied to the

Big Bag emptying stands.

h. PAC SLURRY EDUCTOR

Sodimate engineers custom mixing tanks for various slurry solutions ranging from 2% to 30%. Typical slurry solutions include calcium (hydrated lime or quicklime), powdered activated carbon (PAC), sodium bicarbonate (soda ash), potassium permanganate and

clay. Sodimate tanks are made out of black HDPE, and their design and layout is fully customizable. The tanks come fitted with a mixer, valves, detectors, as well as necessary fittings for pumping, draining, over-flow,

and liquid recirculation. Tanks are dust-free and their volumes typically range from 100gal to 1,000gal. Larger tanks up to 700ft³, made of HDPE, epoxy coated steel, or stainless steel, can also be fabricated.

i. BULK STORAGE SILOS

Bulk storage silos made of steel are the perfect solution to store the powdered reagents like hydrated lime, activated carbon, soda ash, and many other dry chemical powders. The cylindrical shape and the conical bottom allow a complete discharge of the

product when combined with a mechanical arch breaker.Silos have a custom design regarding the local constraints related to the site (snow, wind, seismic data,…). Also to consider: the powder data (product stickiness,

clogging, corrosive …) and the daily consumption.With a volume ranging from 200 to 7,000 ft

3, Sodimate helps to choose the right diameter and height of silos to comply with the technical definition of the customer.Our steel silos are in one-piece construction, with protective linings and coatings,

and ASME certification.Their design integrates each standard and optional custom accessory.

j. SLURRY PUMP SKID

Sodimate’s skid-mounted and pre-piped slurry metering system comes equipped with pumps and all metering accessories needed for easy installation and reliable operation.

The system is most commonly used for hydrated lime , soda ash and activated carbon slurries with concentrations ranging from 2% to 30%. Additionally, the system is configured to work with Sodimate’s slurry

tank and can be equipped with a control system to offer a complete slurry package.

k. SLUDGE MIXER

Sodimate’s MBV sludge mixer is designed for the mixing of sludge and lime to achieve Class B stabilized sludge. The dual-shaft compact mixer can easily be adapted to existing or new sludge stabilization processes for water and wastewater treatment plants.

l. LIME SLAKER

Many high-consumption lime industries use Sodimate quicklime slakers as opposed to using powdered hydrated lime or ready-mixed lime slurry. Our slakers are able to absorb the exothermic reaction of calcium oxide and water, and efficiently separate lime

grit from the highly concentrated calcium hydroxide resulting from the slaking operation.

Sodimate’s lime slakers are fabricated to each customer’s lime specifications and consumption requirements. All our lime slakers can be fully automated and are engineered with several options to minimize

chemical contact with operators and prevent extensive maintenance due to lime coating.